Intel’s revival strategy centers around a multibillion-dollar facility in the Arizona desert. Can this Intel Arizona Factory help the chipmaker regain its former dominance?

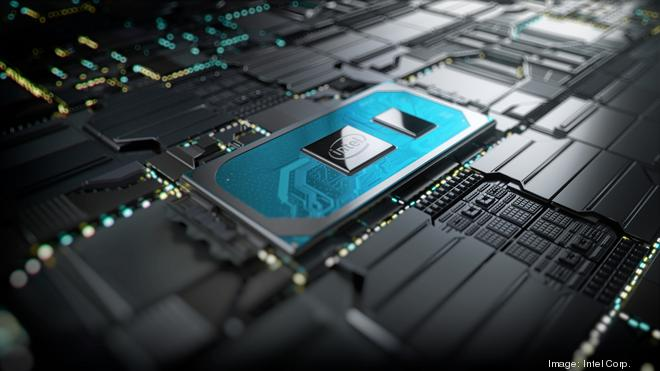

On the arid plains of Phoenix Valley, Intel has invested over $20 billion in a four-story manufacturing complex—Fab 52—at the heart of its ambitious comeback plan. This Intel Arizona Factory introduces a new production method aimed at creating faster, more efficient computer chips using advanced lithography machines from ASML, marking the first time in nearly a decade that Intel produces its most advanced semiconductors in the U.S.

During a recent tour of the Intel Arizona Factory, two $250 million ASML machines sat mostly idle while engineers in sterile white suits conducted maintenance. Nearby spaces remain empty, signaling Intel’s hopes for future expansion. The company has also hosted potential clients at the facility, showcasing its chip production capabilities. However, analysts caution that many chip companies are waiting to see if Intel can successfully produce its own processors before trusting it with their designs for AI, smartphones, and other technologies.

The Intel Arizona Factory symbolizes the pivotal moment in Intel’s comeback. Once a Silicon Valley powerhouse, Intel lost ground to TSMC, which adopted ASML technology faster. Intel was also dropped by Apple due to underperforming chips affecting battery life and laptop performance.

Intel has cycled through several CEOs during its downturn, with Lip-Bu Tan becoming the third chief executive in five years. Tan inherited a fragile balance sheet and a bold plan: roll out five new production technologies in four years while positioning Intel as a manufacturer for other chip designers. Federal support came in the form of an $8.9 billion investment under the CHIPS and Science Act, helping stabilize finances.

The Intel Arizona Factory is central to the technological turnaround. The new 18a manufacturing process and upcoming Panther Lake chips promise stacked transistors, denser layouts, and energy-efficient designs. Chips will be produced in-house rather than outsourced, a strategy that carries high risk but potential industry-changing rewards. Intel aims to deliver AI-enabled laptops capable of running all day, beginning early next year.

Analysts note that Intel’s 18a process lags behind TSMC in defect-free yields, but success at the Intel Arizona Factory could reestablish trust with major buyers like Nvidia and Apple. Scaling up production and attracting clients could enable Intel to fully utilize Fab 52 and expand the facility further.

The stakes are high. Intel is betting the future of its chipmaking dominance on the success of the Intel Arizona Factory—a bold move that could redefine its role in the semiconductor industry.