The rapid rate of innovation in the present-day world is getting faster, and at the core of it, there is advanced manufacturing. The utilization of robotics, artificial intelligence, automation, and digital design technologies is changing the process of imagining, making, and sending tech products to worldwide markets.

What Is Advanced Manufacturing?

Advanced manufacturing is the integration of digital technologies, automation, and data-driven processes aimed at increasing productivity and accuracy. The incorporation of robotics, sensors, additive manufacturing, and analytics results in factories that are smarter and more flexible. Their transformation gives rise to a quicker production cycle, less waste, and uniform quality among different sectors.

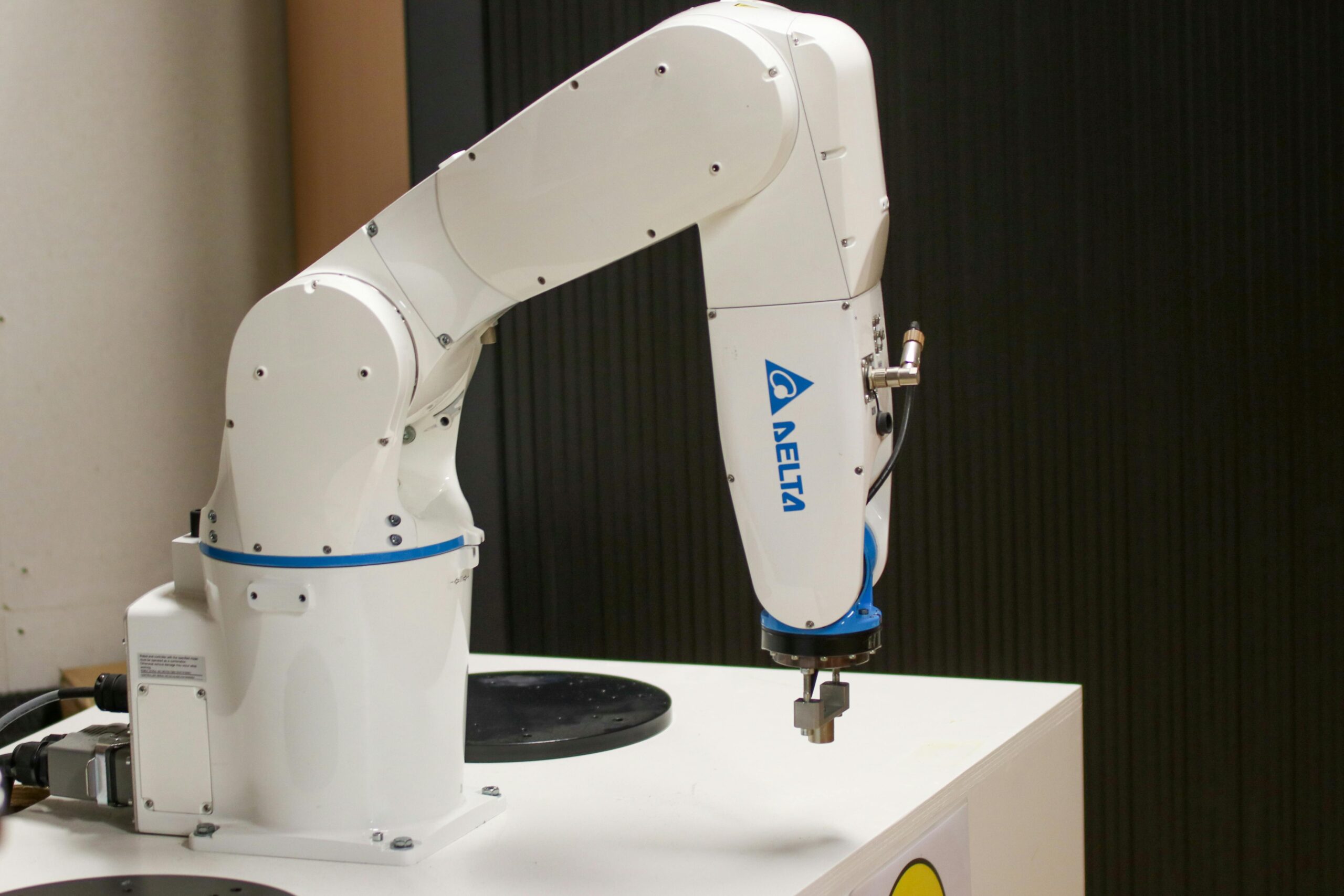

The Rise of Automation and Collaborative Robots

One of the most significant advancements in modern manufacturing is the adoption of collaborative robots — or “cobots.” These smart machines capable of working together with the human operators have been developed to be safe, which means that through their collaboration, efficiency, accuracy, and safety would be improved.

Cobots are involved in the process of electronics assembly, component inspection, and final product packaging. Their versatility gives the manufacturers an opportunity to increase or decrease the number of operations without human fatigue and errors, which is an important factor in the production of high-precision tech.

Driving Innovation in Product Design

Advanced manufacturing has tremendously changed tech companies’ methods in design and prototyping. Engineers using 3D printing and digital twin technology can make and try out complex parts in a virtual environment prior to production. This not only reduces the time for development but also allows the consumer electronics, automotive, and medical devices industries to use cost-effective custom-made products.

Manufacturers that have combined real-time analytics and simulation tools can improve product designs through performance and sustainability, an important point of difference in the present-day competitive global market.

Sustainability and Smart Manufacturing

Modern manufacturing is not only a matter of speed but also of accountability. Smart factories that are endowed with IoT sensors and predictive analytics are capable of optimizing energy consumption, reducing material waste, and encouraging eco-friendly production. The use of advanced recycling methods and the integration of renewable energy sources are among the factors that are assisting manufacturers in reaching their sustainability targets set by the world.

This shift to sustainability guarantees that the technology of the future—ranging from wearables to electric cars—will be made with the least possible harm to the environment.

Shaping the Future of Technology

Insights from TechCrunch and Forbes reveal how Future Technology Trends such as AI-driven automation, quantum computing, and digital supply chains are converging to shape the next wave of manufacturing.

To stay informed about how these innovations will impact global industries, visit TechBillion7 – Future Technology Trends for the latest insights into the technologies driving industrial transformation.

The Road Ahead

The technologies of the Industry 4.0 era will keep changing, and so will the advanced manufacturing, which will be more intelligent, connected, and environmentally friendly. Robots working together, AI, and complete digital assimilation will empower companies to manufacture and ship tech products quickly and in a more intelligent manner than ever.

Conclusion

Manufacturing has come a long way and now uses automation and robotics, AI, and sustainability, to mention a few, as the new order of things. It is a fundamental factor in the making of a new wave of tech devices that are not only better but also more responsible to the environment, thus enacting a future that is all about creativity and smart architecture.