Pneumatic systems are a cornerstone of modern industrial automation, offering reliable and efficient motion control for a variety of applications. Among the essential components in these systems, the double acting pneumatic cylinder plays a critical role in providing controlled linear motion. In this article, we will explore what double acting pneumatic cylinders are, how they work, their types, advantages, applications, and maintenance practices, providing a detailed understanding for engineers, technicians, and enthusiasts alike.

What is a Double Acting Pneumatic Cylinder?

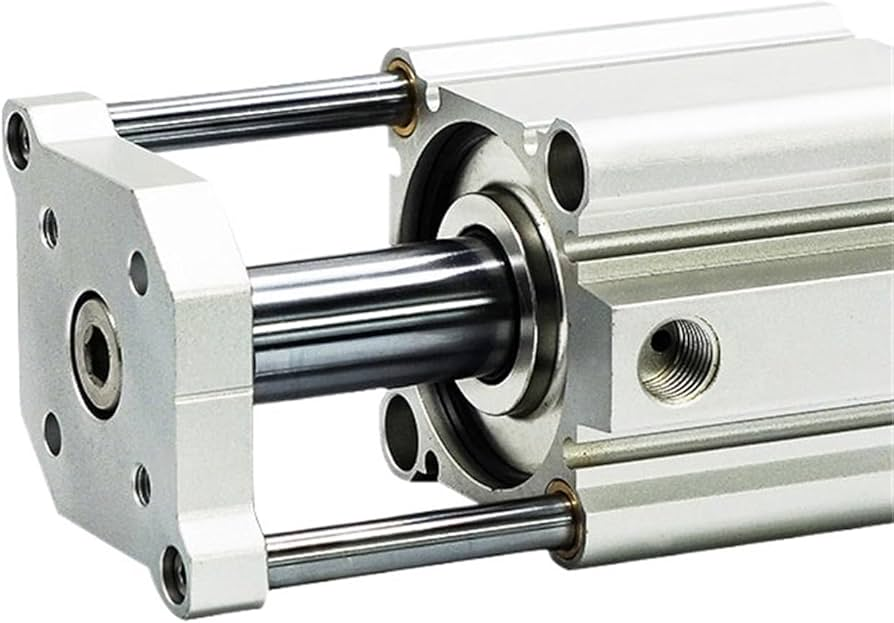

A double acting pneumatic cylinder is a type of actuator that uses compressed air to generate linear motion in two directions: extension and retraction. Unlike single acting cylinders, which rely on a spring or external force to return to their original position, double acting cylinders use air pressure on both sides of the piston to control movement.

This capability makes them ideal for applications that require precise positioning, controlled force, and consistent performance over repetitive cycles. The double acting design is widely used in automation, manufacturing, robotics, and material handling systems.

Components of a Double Acting Pneumatic Cylinder

A typical double acting pneumatic cylinder consists of several key components:

- Cylinder Barrel: The main body where the piston moves. It is designed to withstand high-pressure air and guide the piston smoothly.

- Piston: The moving part inside the cylinder that separates the two air chambers and transfers force to the piston rod.

- Piston Rod: Connects the piston to the external mechanism or load. It transmits the motion generated inside the cylinder.

- End Caps: Located at both ends of the cylinder, they house air ports and provide structural support.

- Seals: Ensure airtight compartments and prevent air leakage during operation.

- Air Ports: Allow compressed air to enter and exit, controlling piston movement in both directions.

Each component is critical to the performance, durability, and efficiency of the cylinder. High-quality materials and precision engineering are essential to maintain smooth operation under repeated cycles.

How a Double Acting Pneumatic Cylinder Works

The operation of a double acting pneumatic cylinder is straightforward but highly effective:

- Extension Stroke: Compressed air enters the port on one side of the piston, pushing the piston rod outward. The air on the opposite side is vented to the atmosphere.

- Retraction Stroke: Compressed air is applied to the opposite port, forcing the piston rod back into the cylinder. The previously pressurized side is vented.

This bidirectional control allows for precise movement in both directions, which is essential for many automation tasks. The speed, force, and stroke length can be adjusted by regulating the air pressure, cylinder size, and flow control.

Types of Double Acting Pneumatic Cylinders

There are several variations of double acting pneumatic cylinders, designed to meet different application requirements:

1. Tie-Rod Cylinders

These cylinders use external tie rods to hold the end caps to the barrel. They are robust, easy to maintain, and commonly used in industrial automation.

2. Compact Cylinders

Compact or short-stroke cylinders are designed for applications with limited space. They provide the same double acting motion in a smaller, lighter package.

3. Guided Cylinders

Guided cylinders include additional rods or bearings to prevent rotation and provide precise linear guidance. These are used in applications requiring accurate positioning and stability.

4. Rodless Cylinders

Rodless cylinders have the piston inside the cylinder connected to an external carriage. The motion is transmitted without a protruding piston rod, making them suitable for space-constrained systems.

Advantages of Double Acting Pneumatic Cylinders

The double acting pneumatic cylinder offers several advantages over other types of actuators:

- Bidirectional Control: Provides controlled movement in both extension and retraction strokes.

- High Force Output: Air pressure can be used effectively on both sides of the piston for greater force.

- Durability: Designed to handle continuous operation in industrial environments.

- Versatility: Can be customized for different stroke lengths, bore sizes, and mounting configurations.

- Precision: Offers consistent and repeatable linear motion.

- Ease of Integration: Compatible with standard pneumatic systems and automation components.

These benefits make double acting cylinders the preferred choice for a wide range of industrial applications.

Applications of Double Acting Pneumatic Cylinders

Double acting pneumatic cylinders are found in numerous industries due to their versatility and reliability. Common applications include:

1. Manufacturing Automation

Used for pushing, pulling, lifting, and positioning materials on assembly lines.

2. Robotics

Provides precise linear motion for robotic arms, grippers, and positioning systems.

3. Packaging Industry

Assists in filling, sealing, cutting, and moving packages on automated conveyors.

4. Material Handling

Used in clamping, ejecting, and moving materials in warehouses or production facilities.

5. Automotive Industry

Operates machinery for stamping, assembling, or transporting automotive components.

Selection Criteria for Double Acting Pneumatic Cylinders

When choosing a double acting pneumatic cylinder, consider the following factors:

- Bore Size: Determines the force output based on air pressure.

- Stroke Length: The distance the piston travels, matching the movement required for the application.

- Mounting Style: Foot, flange, or pivot mounts affect installation flexibility.

- Operating Pressure: Cylinder must be rated for the system’s air pressure.

- Environmental Conditions: Factors like temperature, moisture, and exposure to chemicals influence material choice.

Proper selection ensures optimal performance, longevity, and safety.

Maintenance of Double Acting Pneumatic Cylinders

To maximize the lifespan and performance of a double acting pneumatic cylinder, regular maintenance is essential:

- Inspect Seals and Rods: Replace worn seals to prevent air leakage and contamination.

- Lubrication: Apply appropriate lubrication to reduce friction and wear.

- Check Alignment: Ensure the cylinder and load are properly aligned to prevent uneven wear.

- Monitor Air Quality: Use filters and dryers to prevent moisture and debris from damaging internal components.

- Routine Testing: Periodically cycle the cylinder and check for smooth operation and consistent force.

Following these maintenance practices reduces downtime and improves system reliability.

Common Issues and Troubleshooting

Even well-designed double acting pneumatic cylinders can experience issues. Common problems include:

- Air Leaks: Caused by damaged seals or connections; leads to reduced force and efficiency.

- Rod Misalignment: Can cause uneven wear and hinder piston movement.

- Contamination: Dust or debris can damage seals and cause sticking.

- Pressure Imbalance: Uneven air pressure results in erratic motion.

Addressing these issues promptly ensures safe and efficient operation.

Conclusion

The double acting pneumatic cylinder is an essential component in modern automation and industrial systems. Its ability to provide controlled, bidirectional linear motion makes it invaluable in a wide range of applications, from manufacturing to robotics. Understanding its components, operation, types, and maintenance requirements is key to optimizing performance and ensuring longevity.

Whether you are designing an automated system or maintaining existing machinery, the double acting pneumatic cylinder offers reliability, precision, and versatility that make it a cornerstone of efficient industrial operation