Productivity has always been the driving force behind industrial progress. Whether in a small workshop or a large factory, every manufacturer strives to increase output in less time without sacrificing quality. This is where machining toolsResults now are looking quite promising. These machines are not just for cutting action or drilling motion; their attributes configure precision, efficiency, and innovation-the hallmarks of a truly modern manufacturing era.

From that time, machining technology has come a long way. The tools of the present day are made from superior materials, with automated systems backed by intelligent software. This triad of features enables the industry to run at high speeds along with remarkable reliability and accuracy. Be it the fabrication of heavy-duty metal components or delicate aerospace parts, the right tools operate on the two fundamental principles-speed and precision-which support industrial productivity.

Machining refers to a class of processes that shape, cut, bore, grind, or drill materials such as metals, plastics, and composites based on specific designs. These machining processes were once accomplished mainly through manual labor that could attain only limited accuracy. But the introduction of electrically controlled hydraulic machining tools and a CNC (Computer Numerical Control) system has undergone a tremendous transformation. It is a near-zero human labor, with maximum human intervention required, letting manufacturers produce with near-precision and consistent results; hence, it allows flexibility for mass production.

Machining tools-from ancient hand-operated devices to present-day robotic arms and multi-axis CNC systems-portray the saga of industrial innovation. AI and IoT technologies are increasingly being integrated to monitor machine performance, predict maintenance requirements, and enhance overall equipment effectiveness. This convergence of automation and intelligence has positioned machining at the very spine of the auto, aerospace, energy, and electronics industries.

Modern machining tools have been given relatively better precision and accuracy compared to their predecessors. Tight tolerances are maintained under CNC-driven systems, eliminating the chances of rework; thus, saving time and money. The fascinating thing is that speed has changed quite a lot. Automated tools can perform multiple processes in a matter of minutes, tasks that used to take many hours. Errors are less human; thus, consistency is upheld while allowing workers to take on better roles. The use of durable alloys and coatings enhances the life of these machines while minimizing operational costs and adding reliability.

The lathe, above all, remains the most important machine tool among all machining systems. It operates through rotation that carries the workpiece past a cutting tool, and by means of this, it may perform different operations such as turning, facing, threading, and boring. Lathes will remain forever popular among most of the workshops and factories because, irrespective of CNC and robotic technologies, these are the types on which dependable and variable applications are there.

Across all sectors, cutting-edge machining equipment spells the difference between failure and success in production standards. It is here that the gears, shafts, and internal components of engines are manufactured to precision in the automotive industry. For jet engines, lightweight yet robust turbine blades and other aircraft parts are batch-produced. Microblue machining works in the electronics industry for connectors and circuit boards. Complex energy facilities and machines withstanding even the toughest environments-turbines, pumps, and valves-are built using these tools. The last sector in which machining becomes demanding is medicine, which is getting most of its precision-implying surgical instruments and implants.

Some challenges remain, of course. The cost of acquiring advanced machines may be quite expensive, as well as maintaining them. These machines must be programmed and serviced by skilled personnel, and damage may be due to constant high-speed operations. Furthermore, energy consumption is a major drawback during production on a large scale. However, with proper training, preventive maintenance, and efficient operational management, such problems can be minimized.

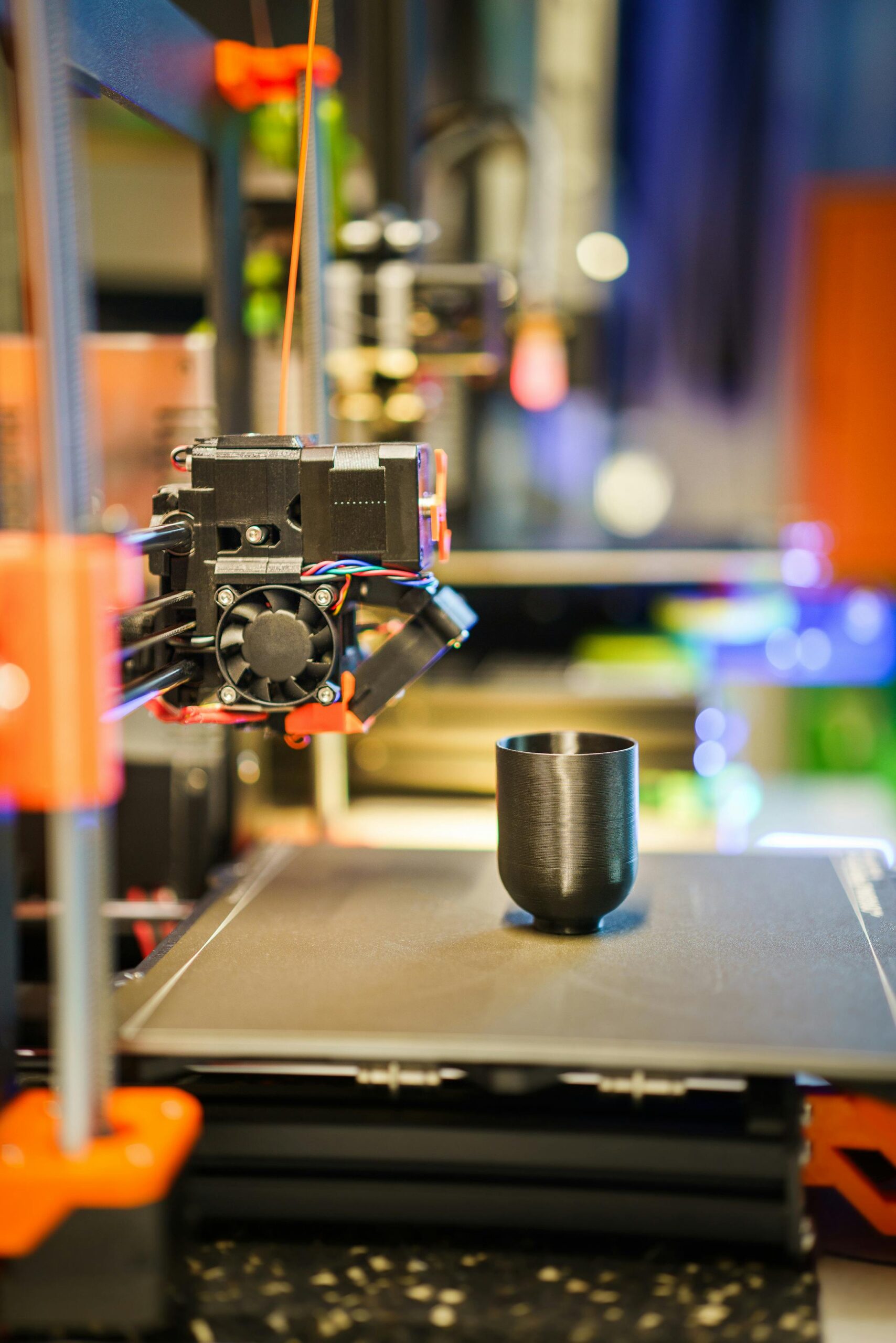

The future of machines will be determined by Future Technology Trends. The data emphasizes smart, integrated, and sustainable manufacturing. Such IoT-enabled systems now collect data in real-time from machines on their performances and record energy consumption, while AI-integration services foresee maintenance needs and optimize production schedules. 3D hybrid machining combines blended additive and subtractive techniques, creating novel design possibilities, and green-tool design reduces waste and energy. Consequently, all these innovations have mutated machining from being a practice into a smarter and greener current practice.

It should be noted that the best maintenance would be possible, regular lubrication of machines, timely replacement of defective parts, and recalibration checks for measurement accuracy on the following basis:- daily, once weekly, and four times a year. Besides, real value lies in skilled operators who know the difference between manual and automated systems well to keep the lines on production lines running. Not to mention that machines have better lifetimes and constant precision.

Simply put, from manual tools to intelligent CNC, they are under the category of machines. Machining tools have revolutionized industrial productivity. They provide the precision, speed, and flexibility needed to remain competitive in a fast-paced global economy. As artificial intelligence, IoT, and hybrid technologies continue to evolve, machining tools will remain at the heart of industrial innovation—driving the Future Technology Trends that define modern manufacturing.