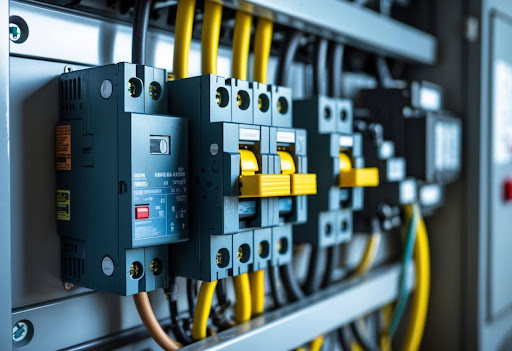

In industrial, commercial, and residential electrical systems, safety and reliability are critical. One key device that ensures both is the motor circuit protector. Often overlooked compared to other electrical components, the motor circuit protector plays a vital role in safeguarding motors and electrical circuits from overcurrent, short circuits, and electrical faults.

This article explores what a motor circuit protector is, how it works, its benefits, types, installation considerations, and why it is essential for modern electrical systems.

What Is a Motor Circuit Protector?

A motor circuit protector (MCP) is an electrical device designed to protect motors and motor control circuits from overcurrent conditions, short circuits, and ground faults. Unlike standard fuses or circuit breakers, MCPs are specifically engineered to handle the unique electrical characteristics of motor loads, which often experience high inrush currents during startup.

Motor circuit protectors are essential for preventing damage to motors, reducing downtime, and enhancing the overall safety of electrical installations.

How a Motor Circuit Protector Works

The motor circuit protector monitors the electrical current flowing through a motor. When the current exceeds the device’s rated threshold due to overload, a short circuit, or a fault, the MCP interrupts the circuit to prevent damage.

Key features of how it operates include:

- Thermal Protection: Reacts to sustained overloads that generate excessive heat.

- Magnetic Protection: Reacts instantly to short circuits or sudden spikes in current.

- Adjustable Settings: Many MCPs allow users to set trip thresholds based on motor ratings.

This dual protection mechanism ensures motors are safe from both gradual overload and sudden faults.

Types of Motor Circuit Protectors

Motor circuit protectors are available in different types to suit various applications:

1. Standard Motor Circuit Protectors

- Designed for general-purpose motor protection.

- Typically rated for a specific voltage and current.

- Suitable for most industrial and commercial motors.

2. Molded Case Motor Circuit Protectors

- Enclosed in a molded housing for enhanced safety.

- Often includes adjustable trip settings.

- Provides protection against both short circuits and overloads.

3. Electronic Motor Circuit Protectors

- Use digital or electronic components to monitor current.

- Provide precise protection and diagnostic capabilities.

- Can integrate with advanced motor control systems.

4. Thermal-Magnetic Motor Circuit Protectors

- Combines thermal and magnetic trip mechanisms.

- Thermal protects against sustained overloads.

- Magnetic responds instantly to short circuits.

Each type offers distinct advantages depending on the application, size, and type of motor being protected.

Key Benefits of a Motor Circuit Protector

1. Enhanced Motor Safety

By preventing overload and short circuits, motor circuit protectors extend the lifespan of motors and reduce the risk of catastrophic failures.

2. Reduced Downtime

MCPs help avoid unexpected motor failures, ensuring continuous operation and productivity.

3. Fire Prevention

Electrical faults can lead to overheating and fires. MCPs mitigate this risk by disconnecting faulty circuits before damage occurs.

4. Cost Savings

Protecting motors reduces repair and replacement costs while minimizing operational downtime.

5. Compliance with Electrical Standards

Many industries require compliance with national and international electrical codes. Using MCPs ensures adherence to safety standards.

Applications of Motor Circuit Protectors

1. Industrial Manufacturing

Motors in factories power conveyors, pumps, compressors, and robotic systems. MCPs prevent costly production stoppages caused by motor failure.

2. Commercial Buildings

HVAC systems, elevators, and escalators rely on motors. MCPs safeguard these systems to ensure building operations run smoothly.

3. Water and Wastewater Treatment

Pumps and motors used in treatment plants require robust protection. MCPs prevent overloads that could damage critical equipment.

4. Renewable Energy Systems

Wind turbines, solar inverters, and other green energy solutions use MCPs to protect motors from unpredictable electrical surges.

Installation Considerations for Motor Circuit Protectors

1. Correct Sizing

Selecting the right MCP is crucial. Consider the motor’s:

- Full-load current

- Startup current (inrush)

- Voltage rating

- Ambient temperature

Proper sizing ensures effective protection without nuisance tripping.

2. Coordination with Other Protective Devices

MCPs often work alongside fuses, contactors, and overload relays. Coordination ensures selective tripping and system reliability.

3. Environmental Factors

Consider the installation environment:

- Indoor vs. outdoor

- Temperature extremes

- Humidity and dust

- Vibration or shock

Some MCPs are designed to withstand harsh industrial environments.

4. Maintenance Access

Ensure that MCPs are easily accessible for testing, maintenance, or replacement. Periodic inspection ensures ongoing reliability.

5. Compliance and Certification

Always use MCPs that meet industry standards, such as UL 489 or IEC 60947, to ensure safety and regulatory compliance.

Motor Circuit Protector vs. Standard Circuit Breakers

While both MCPs and standard circuit breakers protect against overcurrent, MCPs offer specialized advantages for motor applications:

| Feature | Motor Circuit Protector | Standard Circuit Breaker |

| Designed for motor inrush currents | ✅ | ❌ |

| Adjustable trip settings | ✅ | Limited |

| Short circuit and overload protection | ✅ | ✅ |

| Suitable for long-duration motor loads | ✅ | ❌ |

| Integration with motor control systems | ✅ | Limited |

MCPs are preferred for applications with motors due to their ability to handle startup surges and protect sensitive motor components.

Maintenance Tips for Motor Circuit Protectors

- Regular Testing: Periodically test trip functions to ensure proper operation.

- Visual Inspection: Look for signs of overheating, corrosion, or damage.

- Tight Connections: Ensure all electrical connections are secure to prevent arcing.

- Calibration Checks: For adjustable MCPs, verify trip settings align with motor ratings.

- Environmental Cleanliness: Keep MCPs free from dust, moisture, and debris.

Proper maintenance extends the life of both the MCP and the motors it protects.

Emerging Trends in Motor Circuit Protection

1. Smart Motor Circuit Protectors

Next-generation MCPs integrate with IoT and predictive maintenance systems to provide real-time monitoring and alerts.

2. Digital Diagnostics

Modern MCPs can record trip events, helping engineers analyze faults and prevent future issues.

3. Energy Efficiency

Some MCPs now include features to monitor energy consumption and optimize motor performance.

4. Compact Designs

Space-saving MCPs allow for more efficient panel layouts in industrial and commercial installations.

Conclusion

A motor circuit protector is an indispensable component for any electrical system that relies on motors. From industrial machinery to commercial HVAC systems, MCPs provide safety, reliability, and cost savings by protecting motors from overloads, short circuits, and other electrical faults.

By understanding the types, benefits, installation considerations, and maintenance practices, businesses can maximize the efficiency and longevity of their electrical systems. With emerging smart technologies and digital diagnostics, motor circuit protectors continue to evolve, offering even greater protection and operational insight for modern motor-driven systems.

Investing in high-quality MCPs and integrating them into your electrical strategy ensures safer operations, lower downtime, and compliance with safety standards—making motor circuit protectors a cornerstone of reliable and efficient electrical systems.

Electric-motor-circuit-breaker-selection-and-usage-1024x683-1.webp)